First Glimpse into the Production of Skylight Center – Long Thanh International Airport Project

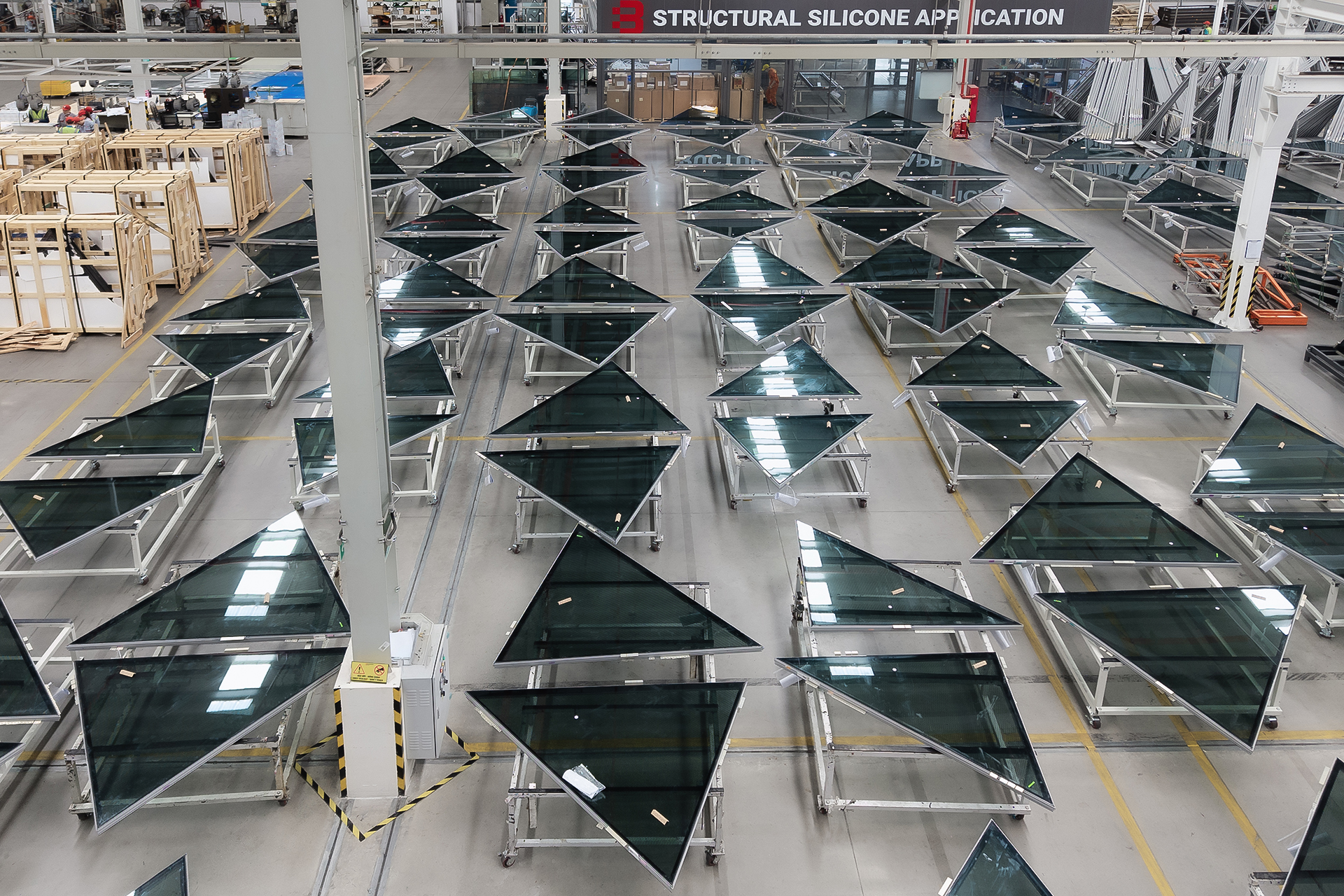

With a total surface area of over 11,000 square meters, the Skylight Center at Long Thanh International Airport is recognized as the largest skylight system in Vietnam to date. At BM Windows' manufacturing facility, production of the first panels is underway with high precision—marking the beginning of one of the most complex and architecturally ambitious façade packages of the entire project.

Thousands of triangular panels are currently being fabricated, inspected, and completed at the BM Windows factory for the Skylight Center – the central roof glazing system of the terminal. This scope includes 5,402 triangular panels with 756 unique geometries, requiring a meticulously organized production process and stringent quality control at every stage—from design, programming, and fabrication to final packaging—executed precisely in accordance with each panel’s specific shape and technical requirements.

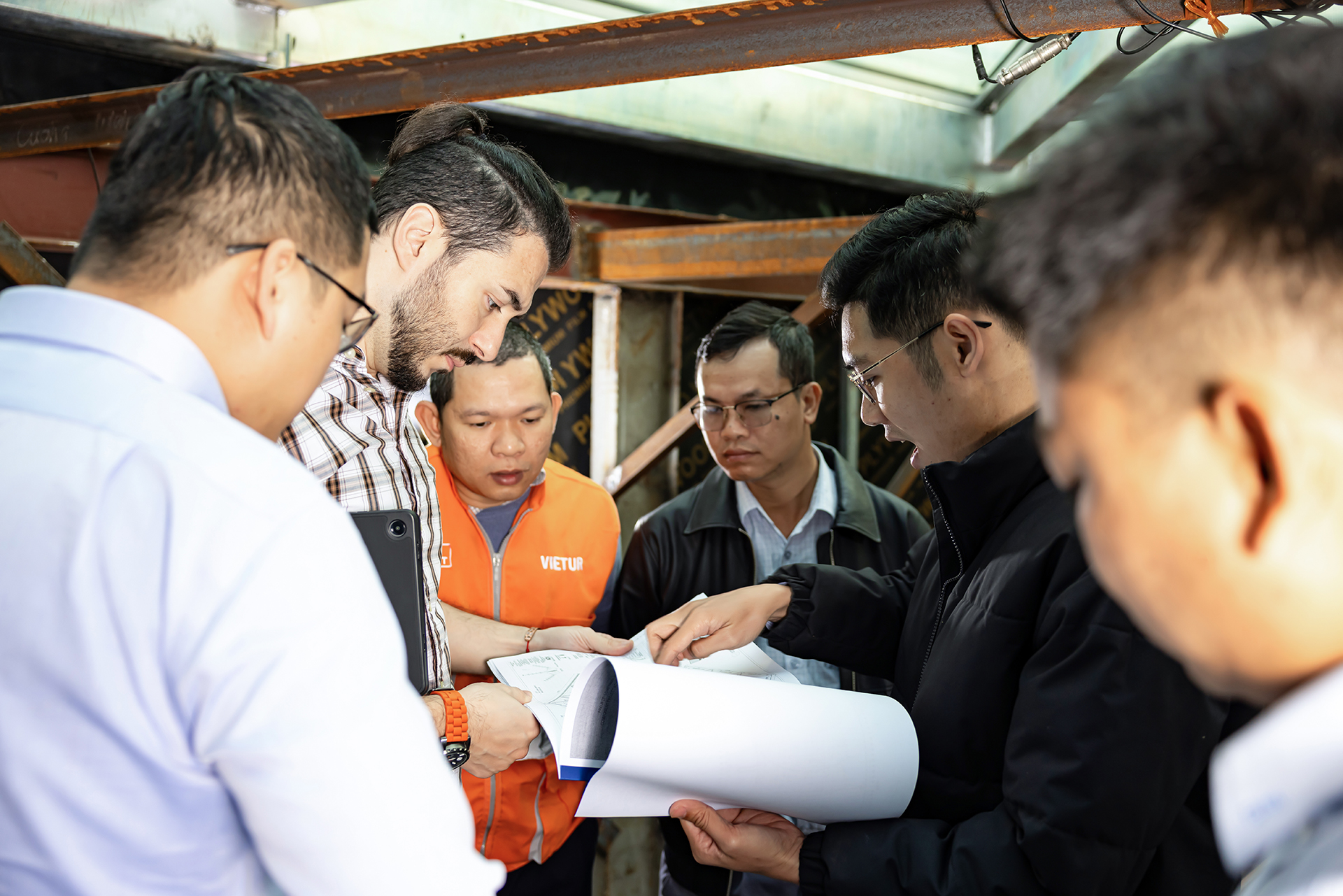

Due to its unprecedented geometric complexity and strict performance requirements, the Skylight Center presents significant challenges in maintaining consistency, dimensional accuracy, and production efficiency throughout the entire supply chain. To meet these demands, BM Windows has implemented a Lean Manufacturing model, optimizing material flow, minimizing waste, and ensuring both timeline and quality are met for every delivery to the construction site.

Furthermore, the Skylight Center is being manufactured in accordance with specialized technical standards for aviation infrastructure, including absolute watertightness, effective sound and thermal insulation, high structural durability, and resistance to wind loads and extreme weather conditions.

All façade components of this project are engineered and produced to meet comprehensive and rigorous performance benchmarks, including: ▪︎ Structural & Physical Performance

▪︎ Energy Efficiency

▪︎ Sound Transmission Control

▪︎ Weather Resistance Performance

▪︎ Air & Water Tightness

BM Windows is proud to contribute to this nationally significant project—beginning with world-class manufacturing capabilities and an unwavering commitment to quality from the very first stage of production.

At BM Windows, each panel is more than just a technical component—it is the result of seamless coordination between engineering, technology, and the shared sense of pride and responsibility carried by our entire team.

related news