Inside the façade production process of 15 Sydney Avenue project

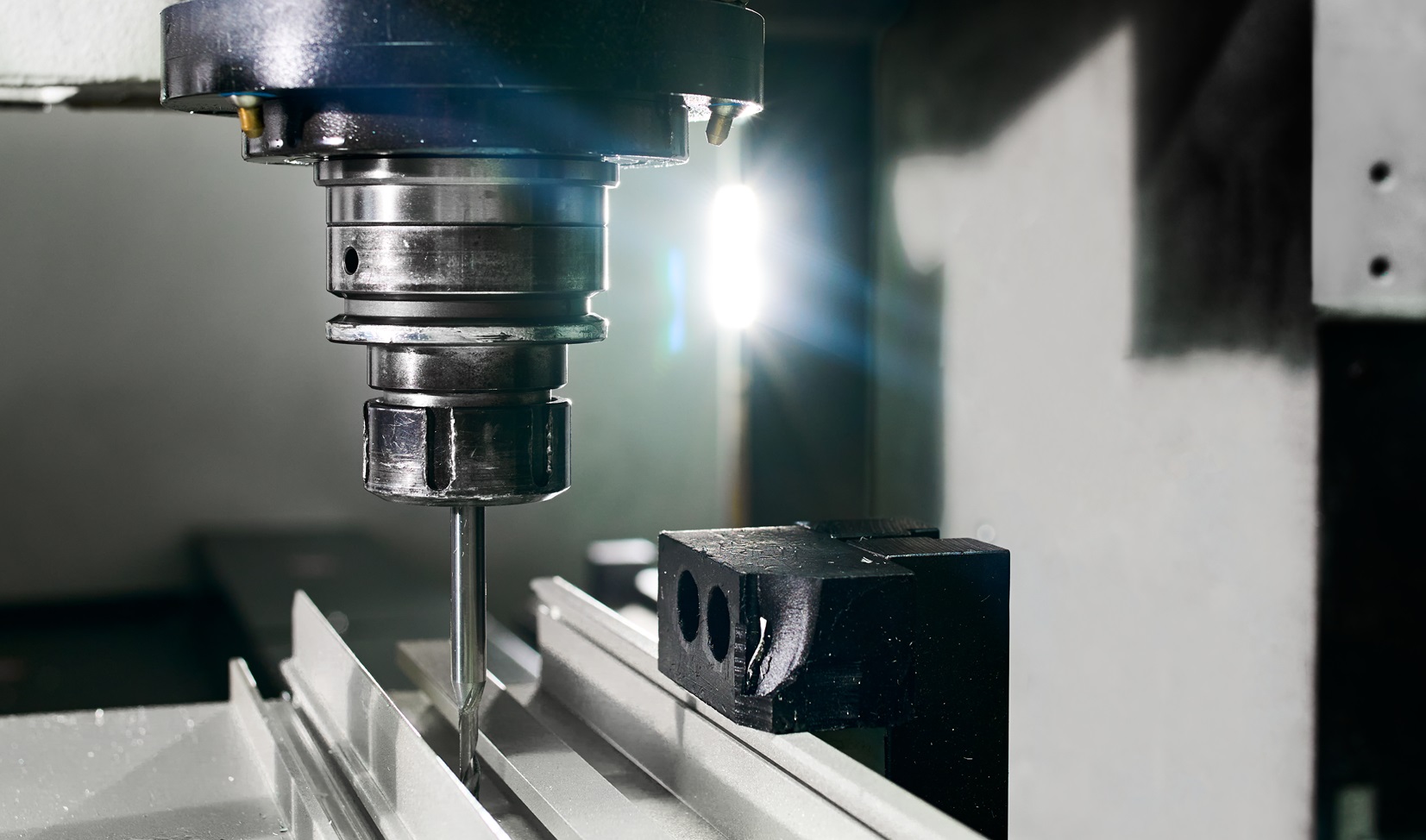

One of the most important techniques for the facade of 15 Sydney Avenue is that the production quality must absolutely meet the waterproofing and airtightness standards, which have been verified according to AS4284. Additionally, all materials used and structural details must comply with Australian market regulations.

The production process for the project is organized by BM Windows through 13 closely coordinated steps within the factory ecosystem, under the supervision of engineers and the expertise of skilled workers, all aimed at ensuring the best quality and timely progress for the project.

Besides technology, it is human expertise that shapes the standard of BM Windows façade engineering.

The pleasure of a smooth beginning truly motivates BM Windows team to become even more determined in our journey to deliver the façade of the 15 Sydney Avenue project.

Each gaze focused on every panel reflects the dedication of craftsmen on every single product, not only at the factory but also throughout its long journey to Australia, supporting the construction and installation efforts on-site.

Appreciating the accompany of our global partners

Throughout the implementation of 15 Sydney Avenue, BM Windows has greatly appreciated the accompany of our global partners who have joined us in this project.

Flights spanning over 7,000 km, weekly meetings, and daily communications have bridged the geographical gap, ensuring that every stage proceeds as seamlessly as possible.

It is the collective efforts and determination of the multiple team that have brought us all together as one, focused on achieving the project's completion in the most professional manner.

related news