One Bloor West – Toronto

Project Overview

The Toronto skyline is undergoing a transformation with the introduction of the international-caliber mega-project, One Bloor West – Toronto, a landmark symbol of Canada. Designed by Foster + Partners and Core Architects, this 85-story tower reaches a height of 308.60 meters and features a modern aesthetic with a unique façade provided by BM Windows.

investor Tridel

location Toronto, Canada

year 2023

area 30,000m² alluminum glass

Project Scale

If New York boasts the One World Trade Center, Dubai the Burj Khalifa, and Shanghai the Shanghai Tower, Toronto is now poised to welcome its first supertall skyscraper – not only a first for the city but also a milestone for Canada. One Bloor West is among fewer than 200 buildings globally that surpass the 300-meter mark in height. With its 85 stories (308,60m), it is set to become the 21st tallest building in the world, standing over 60 meters taller than any other existing building in Canada.

The project was conceived by Foster + Partners and Core Architects, a leading global design firm, and features a range of complex, unique, and refined details. Each challenging aspect of the façade design is executed at an unprecedented level of excellence, unseen in prior Canadian projects. Contributing to the creation of this masterpiece by supplying the façade, BM Windows produced over 38 types of panels, totaling more than 7,000 unitized panel units. The entire façade of the project was manufactured to North American standards, under the strict supervision of ASTM International – the American Society for Testing and Materials.

Technical Challenges

The façade of One Bloor West employs a special structural system that brings the load-bearing cross-bracing to the exterior. Encasing the shimmering glass panels is a three-dimensional aluminum frame, characterized by sharp, crystalline network structures. This design necessitates precise technical solutions for profile systems to ensure seamless panel integration and compliance with the stringent standards of a supertall building, including load-bearing capacity, air and water tightness, and building displacement, among others.

All imported materials fulfill the requirements for load-bearing capacity, building displacement, thermal and sound insulation, air tightness, and durability. Each design detail of the façade system surpasses the highest levels previously unseen in Canadian projects, aimed at mitigating high-altitude pressure risks.

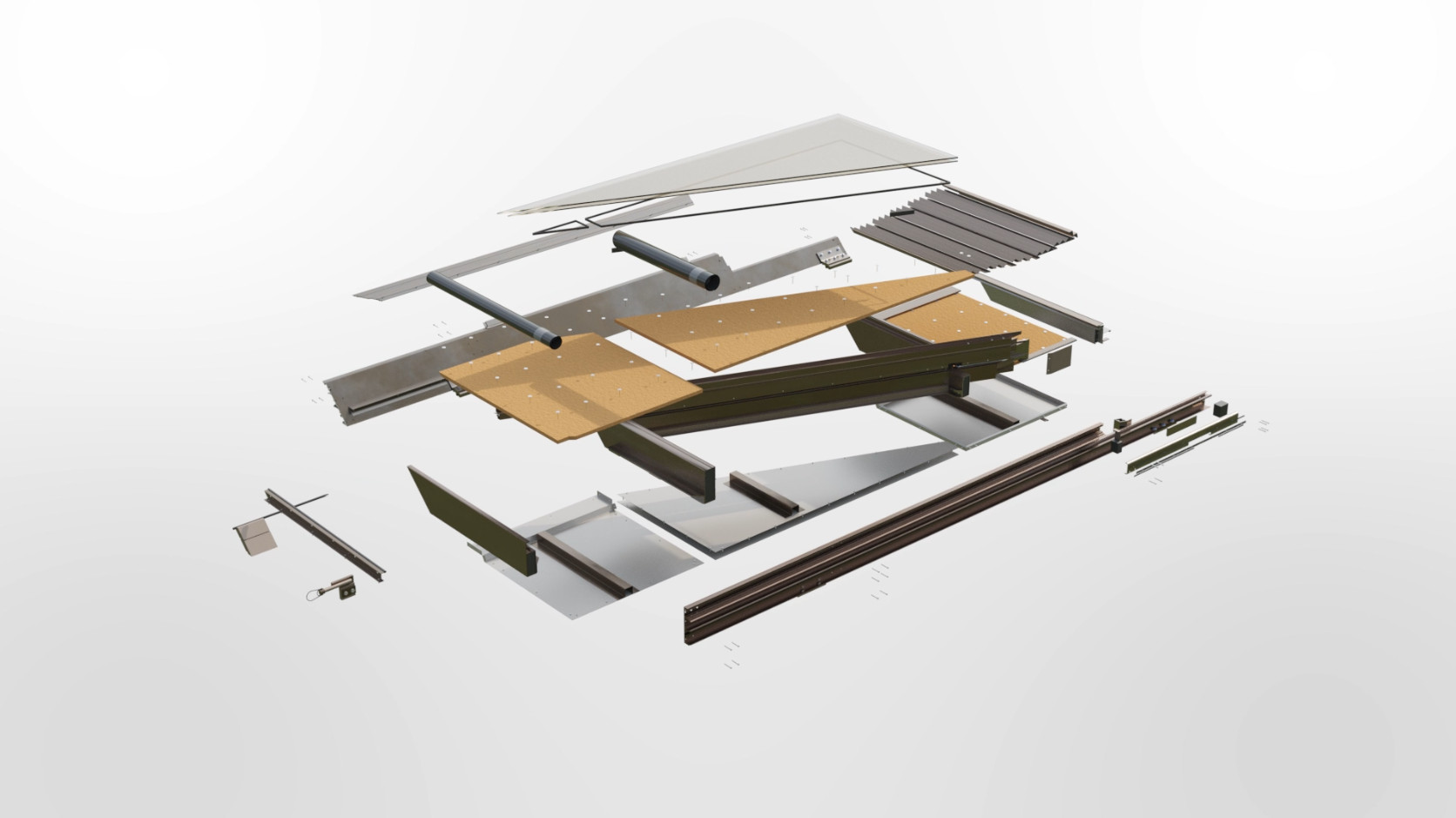

Complexity in Profile Design

In this project, BM Windows is set to produce over 38 distinct types of panels, amassing more than 7,000 unitized panels in total. The entire façade system, manufactured by BM Windows, was subjected to strict scrutiny by ASTM International — the American Society for Testing and Materials. It is designed to endure the severe temperate climate of Canada, with temperatures dropping to -18 degrees Celsius, and to withstand wind pressures at high elevations up to 4.0 kPa.

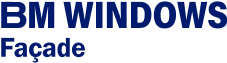

Each unitized panel within the project comprises over 200 distinct parts, including aluminum, glass, thermal breaks, and various other accessories.

One Bloor West's façade embodies the pinnacle of technical specifications for a “supertall” building, conforming to the rigorous standards of the North American region.

16 Steps of Stringent Quality Assurance

One Bloor West's Mockup, featuring 30 panels over an area of 108 m2, is the most extensive and intricate mockup ever tested at Winwall Vietnam. The construction of the (PMU) Mockup necessitated the creation of an oversized laboratory, equipped with a range of devices suitable for the most complex testing procedures to date.

The façade modules of One Bloor West were subjected to tests for air permeability, static and dynamic water penetration, structural integrity, and displacement in both vertical and horizontal directions under varying environmental conditions. Notably, water-tightness testing was a crucial requirement for the project. BM WINDOWS carried out up to six tests for static and dynamic water penetration under differing pressure conditions. Following the structural performance and displacement tests, with up/down ±20 mm and left/right ±13 mm adjustments, One Bloor West's façade system continued to meet the highest standards of water resistance and air tightness.

One Bloor West's Mockup, featuring 30 panels over an area of 108 m2, is the most extensive and intricate mockup ever tested at Winwall Vietnam.

North American Standard Manufacturing Process

One Bloor West project stands out for its complexity and difficulty, featuring over 38 distinct panel types that demand strict technical specifications for manufacturing. BM Windows supplied nearly 7,000 unitized panels for this project, covering a total area close to 30,000 m2. Production for each floor was systematically organized, progressing from panel number 1 to 112, with an average completion time of 4 days per floor. Each panel, comprising over 200 components, was precision-engineered using Elumatec CNC machines.

The testing process, including Backpan water testing, glazing cavity water testing, operational testing of tilt-and-turn windows without glass, operational testing of completed tilt-and-turn windows with glass, and silicone sealant adhesion testing, was carried out concurrently during the production phase. This process was conducted as frequently as required by the project owner, under the supervision of QA/QC.

One Bloor West adheres to a stringent quality control process, not just through internal QA/QC but also via third-party checks, ensuring that all products meet the highest technical standards at every phase. This comprehensive approach spans from the inspection of raw materials and production steps to the final inspection of the completed product before dispatch.

The entire façade system, manufactured by BM Windows, was subjected to strict scrutiny by ASTM International — the American Society for Testing and Materials.

The American Society for Testing and Materials

Contact us

Please leave your contact information and BM Windows will connect with you promptly!

Discover more