QA/QC Process at BM Windows Factory

With a stringent quality management system and advanced production technology, BM Windows factories not only ensure the capacity to deliver world-class projects in Vietnam but also meet the most demanding technical requirements in markets such as the United States, Canada, and Australia...

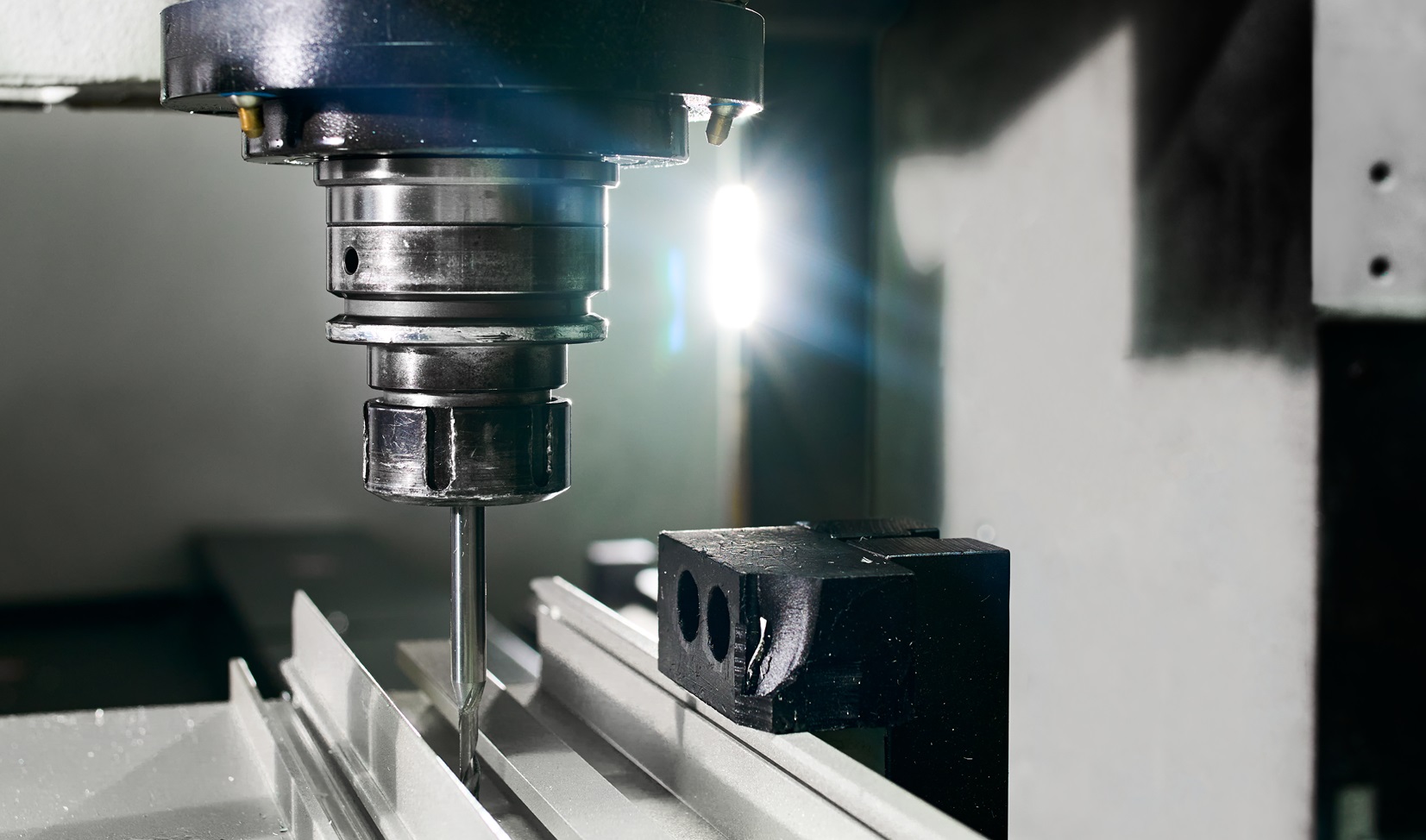

At BM Windows, quality is a core engineering philosophy—embedded in every stage from design and fabrication to assembly and final inspection. The QA/QC (Quality Assurance & Quality Control) system is designed to ensure that every façade component meets international standards of precision, performance, and aesthetics.

The quality control process is implemented through a multi-layer system:

- Material inspection: All aluminum profiles, glass, sealants, gaskets, and accessories are thoroughly tested according to ASTM, EN, and project-specific standards.

- Precision fabrication: Utilizing a fully automated Elumatec (Germany) production line, including high-speed cutting machines operating at 2,250 RPM and new-generation crimping machines with productivity four times higher than conventional technology.

- Process control and testing: Every façade unit is checked using technical checklists and aesthetic criteria, followed by periodic in-house testing for water and air tightness, wind pressure resistance, acoustic performance, and impact resistance.

All operations are managed through an intelligent ERP system, allowing real-time tracking and quality evaluation for each façade panel via batch codes, while BIM-to-CNC data integration ensures perfect synchronization between design and production.

Mastering technology, mastering quality, and above all—mastering people: this is the foundation on which BM Windows continuously advances, affirming its position as a pioneer in façade engineering from Vietnam to the world.

Mastering technology, mastering quality, and above all, mastering people – this is the foundation of BM Windows’ enduring excellence.

BM Windows not only focuses on expanding its scale but, more importantly, on developing technical capability and human expertise – the key factors that ensure precision, consistency, and excellence in every product.

related news